m12 x 1.25 flange nut

Dez . 19, 2024 14:20 Back to list

m12 x 1.25 flange nut

Understanding the M12 x 1.25 Flange Nut An Overview

In the realm of engineering and mechanical connections, the M12 x 1.25 flange nut plays a pivotal role in ensuring the integrity and reliability of various assemblies. This article explores the specifications, applications, benefits, and considerations related to this particular type of fastening hardware.

What is an M12 x 1.25 Flange Nut?

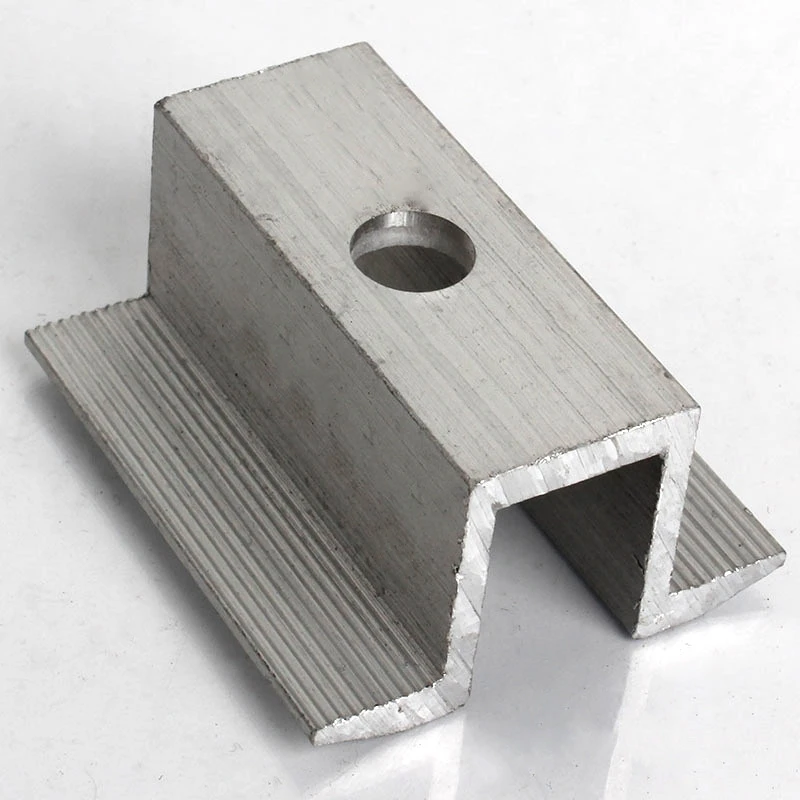

The M12 x 1.25 flange nut is defined by its size and thread pitch. The “M” stands for metric, while “12” indicates the nominal diameter of the nut, which is 12 millimeters. The “1.25” signifies the thread pitch, meaning that the distance between threads is 1.25 millimeters. This type of nut also features a flange—a circular extension at one end that distributes the load over a larger surface area.

Flange nuts are typically designed to be used with bolts of the same size. The M12 x 1.25 flange nut is usually made from various materials, including steel, stainless steel, and sometimes nylon, to suit different environmental conditions and corrosion resistance requirements.

Applications of M12 x 1.25 Flange Nuts

M12 x 1.25 flange nuts are versatile and are commonly utilized in a wide range of applications, such as

1. Automotive Industry These nuts secure components like suspension systems, engines, and transmissions, providing strong connections that can withstand vibrations and torque.

2. Construction In construction, M12 x 1.25 flange nuts are used in structural steel connections, ensuring that beams, columns, and braces are securely fastened.

3. Manufacturing Many machines, equipment, and assemblies in factories rely on these nuts for fastening components due to their reliable performance under high-stress conditions.

4. Furniture Assembly With the rise in flat-pack furniture, flange nuts provide a strong connection for pieces that require assembly, ensuring stability and longevity.

Advantages of using M12 x 1

.25 Flange NutsThere are several benefits to using M12 x 1.25 flange nuts, including

m12 x 1.25 flange nut

1. Load Distribution The flange design helps to distribute load more evenly, reducing the chance of damage to the material being fastened.

2. Prevention of Loosening Flange nuts often have serrations or grooves on the underside of the flange, which grip the surface of the material. This feature helps prevent the nut from loosening due to vibrations or dynamic loads.

3. Ease of Use The larger surface area of the flange provides greater torque, making it easier to tighten the nut securely. Additionally, the flange eliminates the need for a separate washer, simplifying the assembly process.

4. Versatility M12 x 1.25 flange nuts can be used in various materials and environments, making them suitable for different industries and applications.

Considerations When Using M12 x 1.25 Flange Nuts

While M12 x 1.25 flange nuts are beneficial in many applications, a few considerations should be kept in mind

1. Material Selection It is essential to select the appropriate material based on environmental factors such as temperature, humidity, and exposure to corrosive substances.

2. Torque Specifications Proper torque settings should be followed to avoid overstressing the bolt and nut assembly, which could lead to failure.

3. Compatibility Ensure that the nut matches well with the bolt being used. Thread compatibility is crucial for ensuring that the fastening system functions as intended.

4. Installation Proper installation techniques should be followed, including the use of the right tools and techniques, to ensure the reliability of the connection.

Conclusion

The M12 x 1.25 flange nut is a vital component in various mechanical assemblies, offering significant advantages in load distribution and resistance to loosening. Understanding its applications, benefits, and best practices can enhance the effectiveness of your projects, ensuring robust and lasting connections. Whether in automotive, construction, or manufacturing, these nuts play a crucial role in promoting safety, reliability, and performance in mechanical assemblies. As engineering advances, the importance of such fastening solutions will only continue to grow.

Latest news

-

Premium Self Tapping Metal Screws: Strong & Easy Install

NewsAug.02,2025

-

Premium Fasteners Manufacturer | AI-Driven Solutions

NewsAug.01,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | High Strength, Corrosion Resistance

NewsAug.01,2025

-

High-Strength Hot Dip Galvanized Bolts - LongZe | Corrosion Resistance, Custom Sizes

NewsAug.01,2025

-

Best Self Tapping Screws for Drywall - Fast & Secure Installation

NewsJul.31,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&Customization

NewsJul.31,2025