Understanding ASTM A153 Coated Screws for Corrosion Resistance and Durability Applications

Nov . 30, 2024 02:29 Back to list

Understanding ASTM A153 Coated Screws for Corrosion Resistance and Durability Applications

Understanding ASTM A153 Hot-Dip Galvanized Screws

In the realm of construction and manufacturing, the durability and longevity of materials are critical considerations. One standard that serves as a cornerstone in ensuring the corrosion resistance of fasteners, particularly screws, is ASTM A153. This specification outlines the requirements for hot-dip galvanizing, providing a protective coating to metal fasteners that bolsters their performance in various environments.

What is ASTM A153?

ASTM A153 is a standard specification developed by the American Society for Testing and Materials (ASTM). It specifically covers the hot-dip galvanizing of iron and steel hardware, which includes a variety of fasteners such as screws, bolts, and nuts. The process of hot-dip galvanizing involves immersing the prepared metal components in a bath of molten zinc, resulting in a metallurgically bonded coating. This zinc layer significantly enhances the resistance of the metal to corrosive elements.

Importance of Hot-Dip Galvanization

Corrosion is an ever-present challenge in many industries, particularly those exposed to harsh environmental conditions such as coastal areas, industrial settings, or regions with high humidity. Over time, unprotected metal fasteners can deteriorate, leading to structural failures, safety hazards, and costly repairs. Hot-dip galvanization provides a robust defense against this threat.

The zinc coating not only serves as a physical barrier preventing moisture and pollutants from reaching the underlying steel but also acts as a sacrificial anode. This means that even if the coating is scratched or damaged, the exposed steel is protected by the zinc, which will corrode preferentially. This unique characteristic ensures that hot-dip galvanized screws have a significantly longer service life compared to their non-coated counterparts.

Specifications and Testing

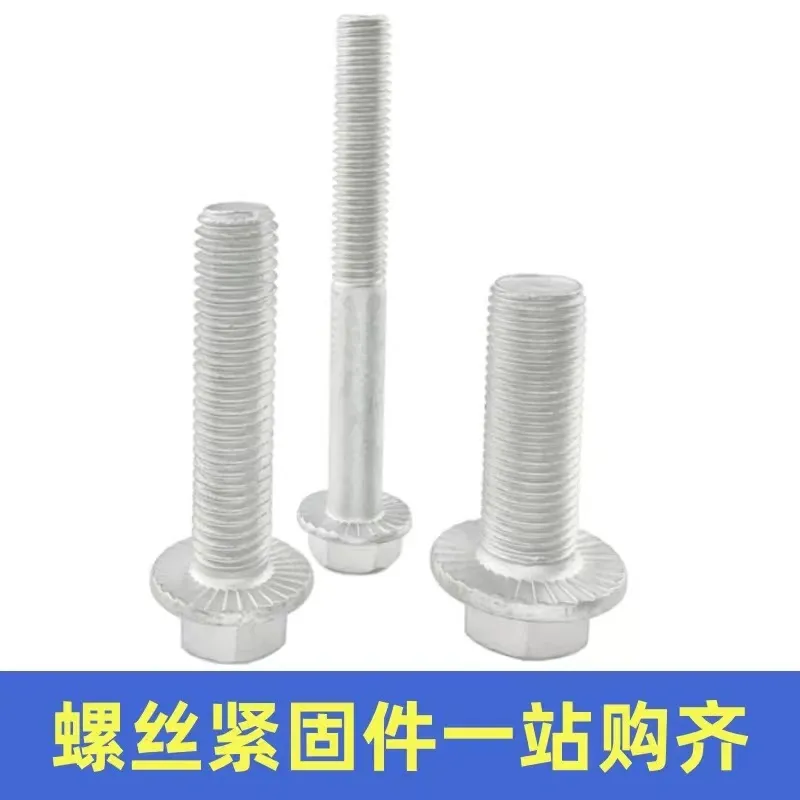

astm a153 screws

Under ASTM A153, various grades of zinc coating are defined, depending on the application and the specific requirements of the project. The specification outlines minimum thicknesses for the zinc layer, which vary according to the mass of the fasteners. Additionally, ASTM A153 the standard includes requirements for the appearance of the coating and the permissible amount of spangle, which is the crystalline appearance that forms during the galvanizing process.

To ensure compliance with ASTM A153, fasteners are subjected to rigorous testing. Common tests include the assessment of coating thickness, adhesion testing, and checks for any uncoated areas or excessive spangle. These tests help manufacturers and users alike confirm that the screws meet the necessary performance and safety standards.

Applications of ASTM A153 Screws

The applications of screws meeting ASTM A153 specifications are vast and varied. Many industries utilize hot-dip galvanized screws, including construction, transportation, and outdoor furniture manufacturing. For instance, in construction, these screws are frequently used for fastening structural components, roofing, and siding materials. Their resistance to rust and corrosion makes them an ideal choice for use in environments where exposure to moisture is guaranteed.

In the agricultural sector, hot-dip galvanized screws are commonly used in the construction of barns and other outdoor structures, ensuring that the fasteners can withstand the elements over time. Their durability extends the lifespan of critical components, leading to lower maintenance costs and improved safety.

Conclusion

The ASTM A153 specification for hot-dip galvanized screws is essential in providing a reliable solution to the problem of corrosion in metal fasteners. By leveraging the benefits of hot-dip galvanization, industries can ensure that their structures and assemblies maintain integrity and safety over their intended lifespan. As we continue to face challenges from environmental factors, understanding and utilizing standards like ASTM A153 becomes increasingly vital in promoting sustainable practices in construction and manufacturing. The choice of materials matters, and opting for ASTM A153-compliant screws is a significant step toward ensuring quality and longevity in any project.

Latest news

-

Hot Dip Galvanized Bolts-About LongZe|High Strength, Corrosion Resistance

NewsJul.30,2025

-

High-Strength Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, Customization

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

High-Strength Hot-Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, High Strength

NewsJul.30,2025