High-Quality M24 Stud Bolts for Reliable Industrial and Construction Applications

আগস্ট . 12, 2024 16:56 Back to list

High-Quality M24 Stud Bolts for Reliable Industrial and Construction Applications

Understanding Stud Bolts A Focus on M24

In the world of engineering and construction, the fasteners we use play a crucial role in the integrity and longevity of structures. Among these fasteners, stud bolts are essential components that facilitate the secure connection of various parts and structures. This article sheds light on stud bolts, particularly focusing on the M24 variant, exploring their applications, specifications, and significance.

What is a Stud Bolt?

A stud bolt is a type of cylindrical bolt that is threaded along its entire length, allowing for efficient attachment and fastening of components. Unlike conventional bolts, which have a fully threaded cylindrical shaft with a head on one end, stud bolts are often utilized in situations where space constraints make it challenging to utilize a standard bolt assembly. In essence, stud bolts often consist of two nuts and a single length of threaded rod, which can be advantageous in various mechanical and structural applications.

Specifications of M24 Stud Bolts

The designation M24 refers to the metric size of the stud bolt, indicating that it has a nominal diameter of 24 millimeters. The M signifies that it follows the metric thread standards, which is common in many industrial applications around the world. The pitch of the threads can vary; however, for standard M24 bolts, a common pitch is 3.0 mm.

Materials used for manufacturing M24 stud bolts are critical, as they must be durable and resistant to various environmental factors. Common materials include carbon steel, stainless steel, and alloy steel, each offering specific advantages such as strength, corrosion resistance, and ease of fabrication.

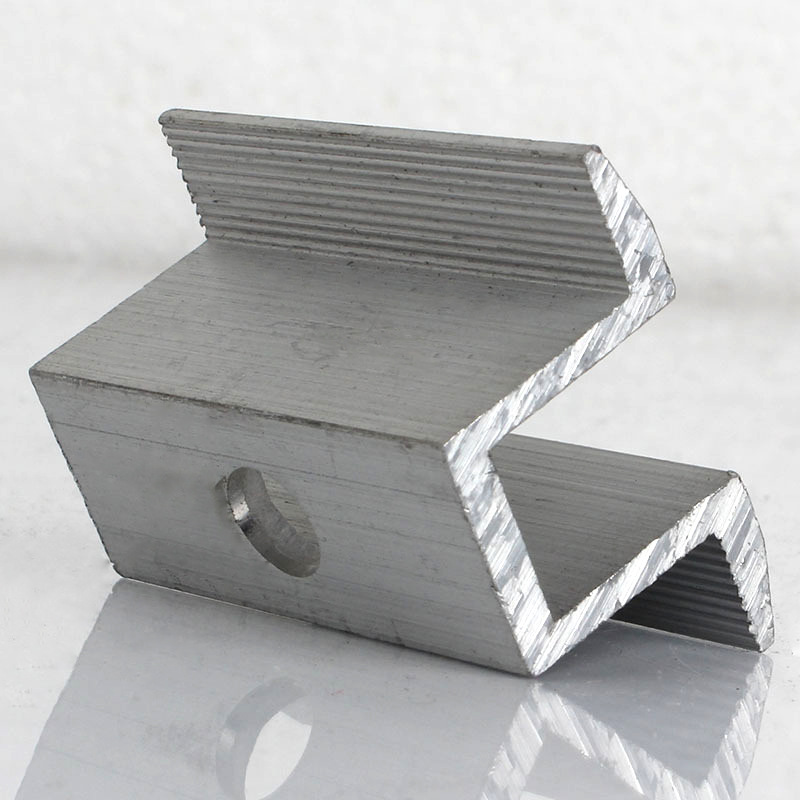

stud bolt m24

Applications of M24 Stud Bolts

M24 stud bolts find utility across a wide range of industries, including construction, automotive, oil and gas, and heavy machinery. Their robust design and high strength make them suitable for high-load applications, such as machinery assembly, structural connections, and pipe flanges in piping systems.

In the construction sector, M24 stud bolts are often used to connect beams, columns, and other structural components to ensure the building's stability and integrity. In the petrochemical industry, they are frequently applied to secure flanged joints under high-pressure conditions, ensuring a leak-proof seal that is vital for safety and efficiency.

Importance of Proper Installation

The effectiveness of M24 stud bolts, like any fastening solution, heavily relies on proper installation practices. Torque specifications are critical; over-tightening can lead to thread stripping or material failure, while under-tightening may result in loosening over time, potentially leading to catastrophic failure in critical applications. It is essential for engineers and technicians to adhere to industry standards and guidelines when installing these fasteners to ensure safety and performance.

Conclusion

In summary, M24 stud bolts are an essential element of modern engineering and construction. Their ability to provide strong, reliable connections in various applications makes them indispensable in many industrial processes. As technology advances and industries evolve, the demand for high-quality fasteners like M24 stud bolts will continue to grow, highlighting the importance of understanding their specifications, applications, and best practices for installation. Whether in a skyscraper, a bridge, or an oil rig, stud bolts play a fundamental role in ensuring that our infrastructure withstands the test of time and the forces of nature. As such, proper selection, maintenance, and installation of M24 stud bolts will remain a cornerstone in achieving safe and long-lasting structural integrity.

Latest news

-

Hot Dip Galvanized Bolts-About LongZe|High Strength, Corrosion Resistance

NewsJul.30,2025

-

High-Strength Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, Customization

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

High-Strength Hot-Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, High Strength

NewsJul.30,2025