black flat washers

নভে. . 23, 2024 01:10 Back to list

black flat washers

Understanding Black Flat Washers Versatility and Applications

Black flat washers are essential components in various mechanical and construction applications. Their primary function is to distribute the load from a fastener, such as a screw or bolt, over a larger surface area, thus reducing the risk of deformation and ensuring a more secure fit. While washers may seem like simple devices, their impact on the durability and reliability of assembled products cannot be overstated.

What are Black Flat Washers?

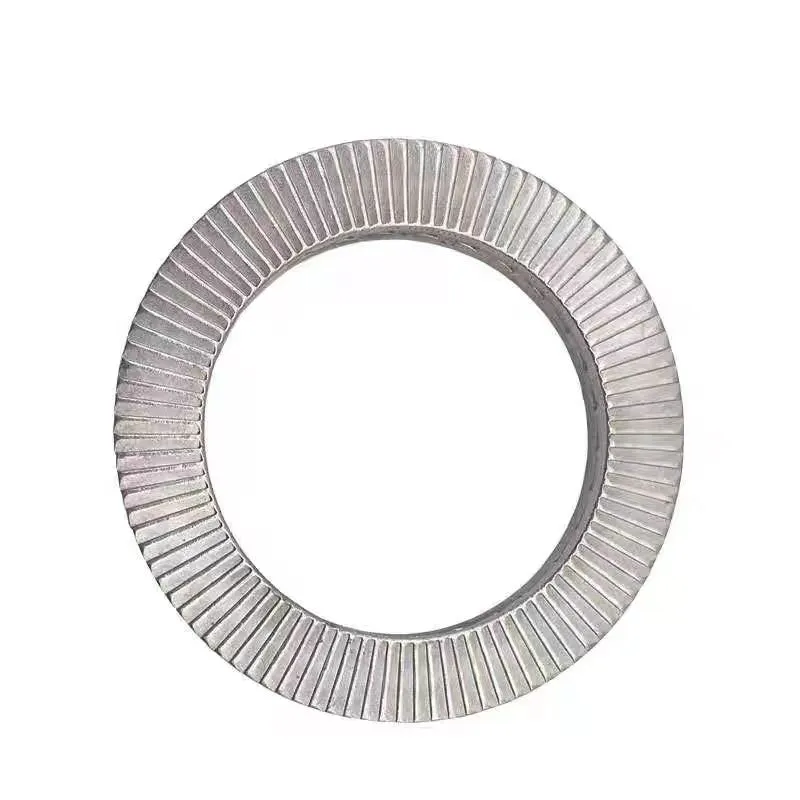

Flat washers are thin, disc-shaped pieces typically made of materials such as metal or plastic. The 'black' in black flat washers often refers to a type of finish applied to steel washers, commonly black oxide or other protective coatings. This black finish not only provides a sleek aesthetic but also improves corrosion resistance, making them ideal for use in harsh environments.

The standard dimensions of flat washers include inside diameter (ID), outside diameter (OD), and thickness, which can vary depending on the intended application. Black flat washers may be categorized into metric and imperial sizes, accommodating a variety of fastener specifications.

Applications of Black Flat Washers

1. Mechanical Assemblies Black flat washers are widely used in mechanical assemblies for automobiles, machinery, and equipment. They help secure bolts and screws in place, prevent loosening during operation, and enhance the overall structural integrity.

2. Construction In construction settings, black flat washers are utilized in conjunction with nuts and bolts to secure structural components, ensuring that loads are evenly distributed across surfaces, which prevents damage to materials like wood or metal.

black flat washers

3. Electronics The electronics industry also benefits from black flat washers. They are often employed in assembling circuit boards and other electronic devices, where their non-conductive surfaces can prevent electrical shorts and improve overall device durability.

4. Home Improvement Projects DIY enthusiasts frequently use black flat washers in their home improvement tasks. Whether fixing furniture or assembling outdoor structures, these washers provide necessary support and stability.

Advantages of Using Black Flat Washers

One of the primary advantages of black flat washers is their protective finish. The black coating acts as a barrier against moisture and other environmental factors, increasing the lifespan of the washers and the components they support. Additionally, in aesthetic applications, the black finish can provide a uniform appearance, which is especially important in visible installations.

Furthermore, the availability of various sizes and thicknesses ensures that black flat washers can be used in numerous applications, making them a versatile choice for engineers and contractors alike. Their cost-effectiveness also plays a significant role in their widespread adoption across industries.

Conclusion

In conclusion, black flat washers are small yet mighty components that play a crucial role in various mechanical, construction, and electronic applications. Their ability to distribute loads, enhance durability, and offer corrosion resistance makes them invaluable to many engineering processes. As industries continue to evolve and demand high-quality materials, the importance of black flat washers remains steadfast. Whether for professional use or personal projects, understanding their functionalities will undoubtedly aid in making informed decisions and ensuring successful outcomes in assembly tasks.

Latest news

-

Hot Dip Galvanized Bolts - Hebei Longze | High Strength, Corrosion Resistance

NewsAug.01,2025

-

High-Strength Hot Dip Galvanized Bolts - LongZe | Corrosion Resistance, Custom Sizes

NewsAug.01,2025

-

Best Self Tapping Screws for Drywall - Fast & Secure Installation

NewsJul.31,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&Customization

NewsJul.31,2025

-

Hot Dip Galvanized Bolts-Hebei Longze Metal Products|Corrosion Resistance&High Strength

NewsJul.31,2025

-

Hot Dip Galvanized Bolts-About LongZe|High Strength, Corrosion Resistance

NewsJul.30,2025