Understanding the Characteristics and Applications of GI Stud Bolts in Construction

ное. . 10, 2024 09:03 Back to list

Understanding the Characteristics and Applications of GI Stud Bolts in Construction

Understanding GI Stud Bolts Essential Components in Engineering

Introduction

In the realm of engineering and construction, the importance of fasteners cannot be overstated. Among these, GI (Galvanized Iron) stud bolts hold a significant place due to their durability and resistance to corrosion. This article delves into the characteristics, applications, and advantages of GI stud bolts, emphasizing their essential role in various industries.

What are GI Stud Bolts?

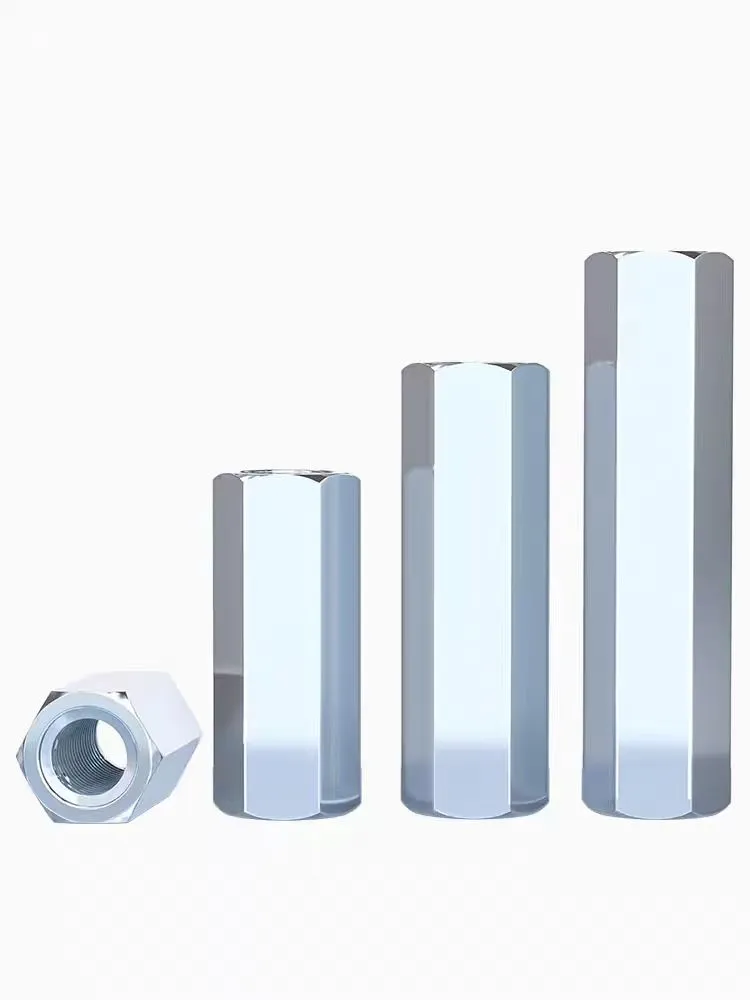

GI stud bolts are threaded fasteners made from iron that has been coated with a layer of zinc through a process called galvanization. This coating provides protection against rust and corrosion, making them ideal for use in outdoor or humid environments. The studs are typically designed to be used in conjunction with nuts and are commonly utilized in connecting two or more objects, particularly in the construction and manufacturing sectors.

Characteristics of GI Stud Bolts

1. Corrosion Resistance The galvanization process creates a barrier that protects the iron from moisture and environmental elements that can lead to rust. This feature significantly extends the lifespan of the fasteners.

2. Strength and Durability GI stud bolts are known for their robust construction, providing excellent tensile strength. This makes them suitable for heavy-duty applications where high load-bearing capacity is required.

3. Versatility Available in various sizes and lengths, GI stud bolts can be tailored to meet specific project requirements, making them suitable for a wide range of applications.

4. Cost-Effectiveness Compared to their stainless steel counterparts, GI stud bolts offer a more economical solution while still providing adequate corrosion resistance and mechanical strength.

Applications of GI Stud Bolts

GI stud bolts are extensively used across numerous industries. Some prominent applications include

gi stud bolt

1. Construction In building structures, GI stud bolts are commonly used to secure beams, columns, and other structural components. Their strength ensures that constructions can withstand various physical stresses.

2. Automotive Industry These fasteners are also vital in the automotive sector, where they are used in assembling different vehicle parts that require a secure hold.

3. Marine Industry Given their resistance to harsh environmental conditions, GI stud bolts find use in shipbuilding and other marine applications where exposure to water is common.

4. Industrial Equipment Machinery and equipment often require welding or assembly, and GI stud bolts provide a reliable solution for connecting critical components.

Advantages of Using GI Stud Bolts

1. Enhanced Longevity The galvanized coating significantly increases the lifespan of the bolts by preventing rust, which can compromise their integrity.

2. Ease of Installation The threaded design allows for straightforward installation, saving time and labor costs during assembly.

3. Sustainability While iron is a recyclable material, the use of galvanized iron supports sustainable practices by extending the lifecycle of construction materials.

4. Aesthetic Appeal The smooth finish of galvanized bolts often leads to a more visually appealing assembly, important in applications where appearance is a consideration.

Conclusion

GI stud bolts are a critical component in modern engineering and construction. Their combination of strength, corrosion resistance, and cost-effectiveness makes them a preferred choice for various applications. Understanding the properties and uses of these fasteners is essential for professionals in the industry, ensuring projects are completed safely and efficiently. As technology progresses and the need for durable materials continues to rise, GI stud bolts will undoubtedly remain a cornerstone in engineering practices.

Latest news

-

High-Strength Hot Dip Galvanized Bolts - LongZe | Corrosion Resistance, Custom Sizes

NewsAug.01,2025

-

Best Self Tapping Screws for Drywall - Fast & Secure Installation

NewsJul.31,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&Customization

NewsJul.31,2025

-

Hot Dip Galvanized Bolts-Hebei Longze Metal Products|Corrosion Resistance&High Strength

NewsJul.31,2025

-

Hot Dip Galvanized Bolts-About LongZe|High Strength, Corrosion Resistance

NewsJul.30,2025

-

High-Strength Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, Customization

NewsJul.30,2025