m10 x 1.25 flange nut

نوفمبر . 11, 2024 18:06 Back to list

m10 x 1.25 flange nut

Understanding M10 1.25 Flange Nuts A Comprehensive Overview

In the world of fasteners, the M10 1.25 flange nut stands out for its unique design and practical applications. These nuts play a crucial role in assembling and securing various components across numerous industries, from automotive to construction. This article delves into the specifics of M10 1.25 flange nuts, exploring their dimensions, features, advantages, and applications.

What is an M10 1.25 Flange Nut?

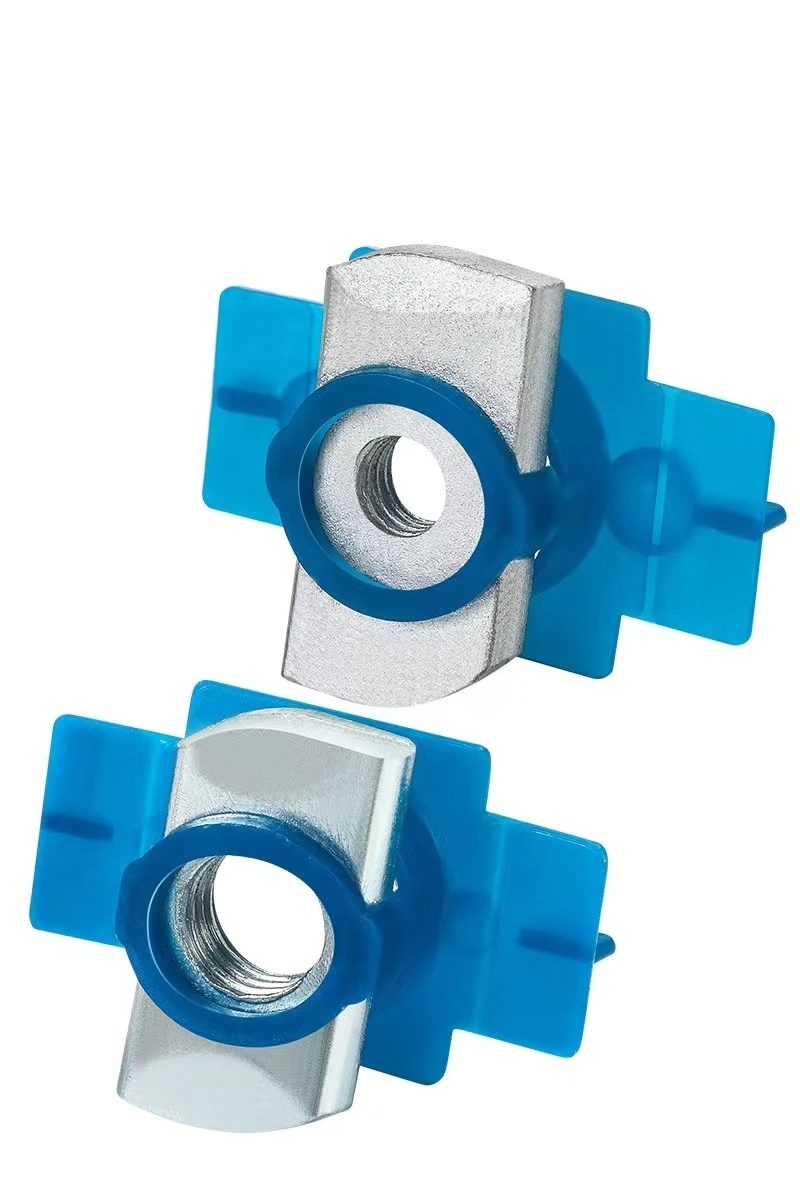

An M10 1.25 flange nut is a type of nut with a specified metric thread size of M10, which corresponds to a nominal diameter of 10 mm. The '1.25' refers to the pitch, denoting the distance between threads, which is 1.25 mm in this case. One of the defining characteristics of this nut is its flange—a protruding rim that helps distribute the load and prevents the nut from loosening under vibration. The flange also serves to create a larger bearing surface, reducing the risk of damage to the bolted parts.

Key Features

1. Material Composition M10 1.25 flange nuts are available in various materials, including stainless steel, carbon steel, and nylon. Stainless steel variants are particularly favored for their corrosion resistance, making them suitable for outdoor and marine applications.

2. Thread Standardization The M10 designation follows the metric thread standard established by ISO (International Organization for Standardization). This standardization ensures compatibility with corresponding M10 bolts and screws, facilitating easy assembly and disassembly.

3. Flange Design The flange serves multiple purposes—it enhances load distribution and stabilizes the assembly, reducing the chances of failure due to loosening caused by vibrations or shock loading.

4. Easy Installation Unlike standard nuts, which may require a separate washer to secure the connection, flange nuts come integrated with the flange design, simplifying the installation process.

5. Variety of Finishes Depending on the application requirements, M10 1.25 flange nuts can come in various finishes, such as zinc plating, black oxide, or even phosphate coating. These finishes not only enhance aesthetic appeal but also improve resistance to wear and corrosion.

Advantages of Using M10 1

.25 Flange Nutsm10 x 1.25 flange nut

1. Improved Load Distribution The flange design allows for a broader contact area with the surface of the material being fastened, which effectively distributes the load and minimizes the risk of distortion or failure.

2. Reduced Loosening Due to the greater surface area and the integrative feature of the flange, these nuts are less likely to come loose over time, especially in applications subjected to vibrations.

3. Cost-Effective In many cases, using flange nuts can reduce the overall cost of assembly. The elimination of separate washers and the potential for lower maintenance due to reduced loosening result in economic advantages.

4. Versatility in Applications M10 1.25 flange nuts are used in a variety of sectors, including automotive, machinery, furniture production, and civil engineering. Their versatility makes them a go-to choice for engineers and designers alike.

Applications of M10 1.25 Flange Nuts

Flange nuts find their application in numerous industries, including

- Automotive Industry Used in assemblies of engines, tires, and chassis where secure fastening is crucial due to the presence of vibrations during operation. - Construction Often employed in steel structures and frameworks, where strength and reliability are paramount.

- Home and Furniture Assembly Used in the manufacturing of various furniture items, where ease of installation and removal is beneficial.

- Industrial Machinery Commonly seen in the assembly of machines that experience significant movement and stress.

Conclusion

M10 1.25 flange nuts are an essential component in many mechanical assemblies, notable for their efficiency and robust design. Their unique flange feature enhances load distribution and stability, making them a preferred choice in various sectors. As technology continues to evolve, the demand for such versatile fasteners will likely grow, driving innovation in materials and designs to meet the ever-changing demands of modern engineering. Whether you are a professional engineer, a DIY enthusiast, or simply someone looking to understand more about fasteners, M10 1.25 flange nuts represent a fascinating and essential element of modern manufacturing and assembly practices.

Latest news

-

Premium Self Tapping Metal Screws: Strong & Easy Install

NewsAug.02,2025

-

Premium Fasteners Manufacturer | AI-Driven Solutions

NewsAug.01,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | High Strength, Corrosion Resistance

NewsAug.01,2025

-

High-Strength Hot Dip Galvanized Bolts - LongZe | Corrosion Resistance, Custom Sizes

NewsAug.01,2025

-

Best Self Tapping Screws for Drywall - Fast & Secure Installation

NewsJul.31,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&Customization

NewsJul.31,2025