threaded fasteners

Feb . 12, 2025 09:45 Back to list

threaded fasteners

Threaded flat washers, typically overshadowed by their flashier fastener counterparts, are indispensable components in many industrial and construction applications. These seemingly simple devices play critical roles in enhancing load distribution, preventing wear, and ensuring tight, secure joining surfaces. Here's an insightful journey into the world of threaded flat washers, focusing on their importance and practical application in various projects.

For projects requiring precision and detailed attention, such as aerospace and high-tech manufacturing, threaded flat washers are central to quality assurance standards. Their use is often dictated by stringent engineering practices that call for verified load and torque specifications. Implementing washers that meet industry standards like ISO or BS guarantees that they will perform as expected under prescribed conditions, boosting the trustworthiness of the assembled components. Moreover, the installation of threaded flat washers is straightforward yet requires a fundamental understanding of the entire fastener assembly process. Improper installation, such as uneven torque application or not using a washer when required, can nullify the washer's benefits. Therefore, proper training and adherence to installation guidelines are crucial, especially in fields where human safety and high-value assets are at stake. An often underappreciated aspect of threaded flat washers is their role in cost efficiency. Although they are relatively low-cost components, their impact on reducing maintenance frequency and preventing equipment failure can lead to significant savings. Businesses, therefore, are wise to invest in high-quality washers that align with the overall quality of their projects. Experienced procurement specialists typically emphasize this aspect, ensuring that every purchase aligns with both short-term and long-term organizational goals. In summary, threaded flat washers, though seemingly modest, embody essential engineering principles that contribute to the success and reliability of countless applications. Their ability to distribute load, protect surfaces, and maintain secure joints under varying conditions underscores their value. In projects where precision, durability, and safety are non-negotiable, threaded flat washers provide a reliable solution that meets and often exceeds expectations. Recognizing their importance and selecting the right type and material can significantly enhance project outcomes, securing a foundational trust in the robustness of the entire assembly.

For projects requiring precision and detailed attention, such as aerospace and high-tech manufacturing, threaded flat washers are central to quality assurance standards. Their use is often dictated by stringent engineering practices that call for verified load and torque specifications. Implementing washers that meet industry standards like ISO or BS guarantees that they will perform as expected under prescribed conditions, boosting the trustworthiness of the assembled components. Moreover, the installation of threaded flat washers is straightforward yet requires a fundamental understanding of the entire fastener assembly process. Improper installation, such as uneven torque application or not using a washer when required, can nullify the washer's benefits. Therefore, proper training and adherence to installation guidelines are crucial, especially in fields where human safety and high-value assets are at stake. An often underappreciated aspect of threaded flat washers is their role in cost efficiency. Although they are relatively low-cost components, their impact on reducing maintenance frequency and preventing equipment failure can lead to significant savings. Businesses, therefore, are wise to invest in high-quality washers that align with the overall quality of their projects. Experienced procurement specialists typically emphasize this aspect, ensuring that every purchase aligns with both short-term and long-term organizational goals. In summary, threaded flat washers, though seemingly modest, embody essential engineering principles that contribute to the success and reliability of countless applications. Their ability to distribute load, protect surfaces, and maintain secure joints under varying conditions underscores their value. In projects where precision, durability, and safety are non-negotiable, threaded flat washers provide a reliable solution that meets and often exceeds expectations. Recognizing their importance and selecting the right type and material can significantly enhance project outcomes, securing a foundational trust in the robustness of the entire assembly.

Next:

Latest news

-

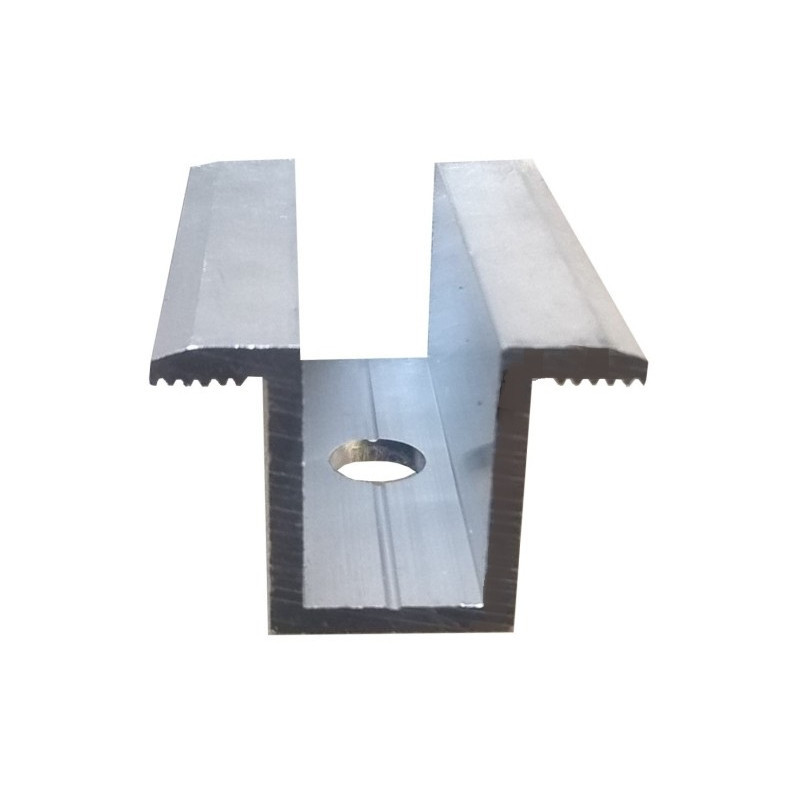

Durable Solar Panel Brackets For Sale | Roof Mounting Kits

NewsAug.15,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance, High Strength

NewsAug.15,2025

-

High-Strength Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, Grade 8.8

NewsAug.14,2025

-

Hot Dip Galvanized Bolts: High-Strength Corrosion-Resistant Fasteners | Hebei Longze

NewsAug.14,2025

-

High-Strength Hot Dip Galvanized Bolts - LongZe Metal Products|Corrosion Resistance&Customizable

NewsAug.14,2025

-

10 Different Types of Fasteners: Auto & Anchor Guide

NewsAug.14,2025