serrated flange lock nut

Nov . 05, 2024 01:07 Back to list

serrated flange lock nut

The Serrated Flange Lock Nut A Reliable Solution for Secure Fastening

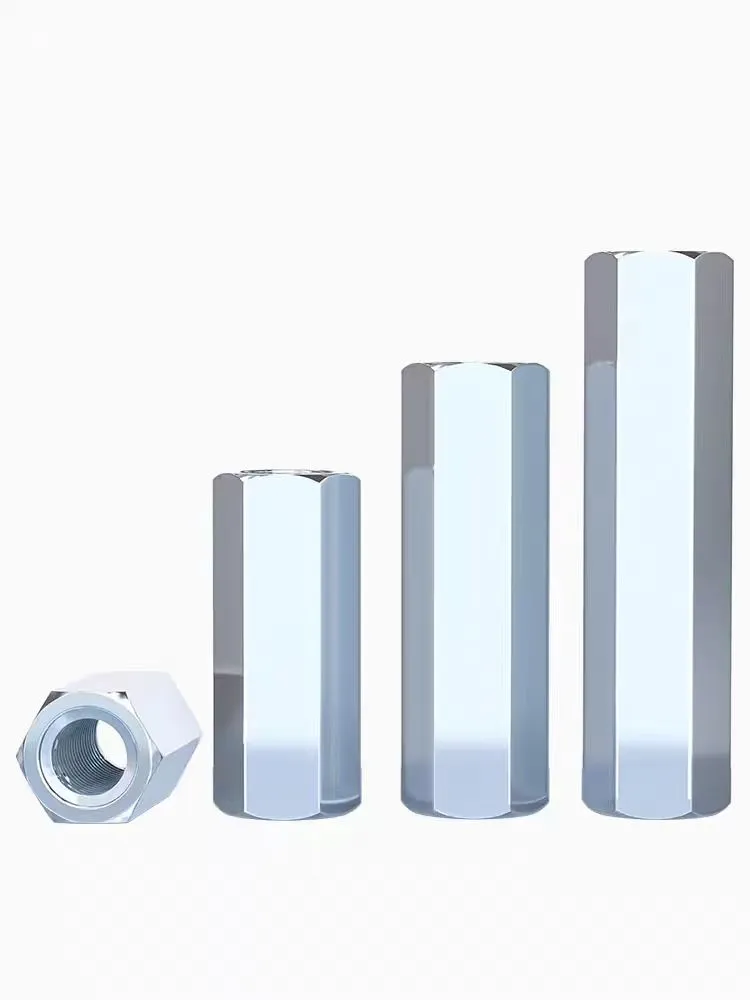

The serrated flange lock nut is an innovative fastening solution widely recognized for its reliability and effectiveness in various industrial applications. These lock nuts play a critical role in ensuring the stability and longevity of assembled products, significantly reducing the risk of loosening under vibrational stresses. This article delves into the design, functionality, and applications of serrated flange lock nuts, highlighting why they are favored in engineering and manufacturing sectors.

Design Features

The serrated flange lock nut combines two essential components a traditional nut and an integrated flange with serrated edges. The serrated edges provide a keyed effect, which enhances the nut's grip on the mating surface. Typically constructed from robust materials such as steel, stainless steel, or other alloys, these lock nuts are designed to withstand harsh conditions while resisting corrosion and wear.

One of the most significant advantages of the serrated flange design is its ability to distribute the load evenly across the surface. This distribution minimizes the risk of damage to the workpieces and maintains the integrity of the assembled parts. Additionally, the flange acts as a washer, eliminating the need for separate washers in many applications.

Functionality

The primary functionality of serrated flange lock nuts lies in their ability to prevent loosening during operation. When subjected to vibration or dynamic loads, traditional nuts can back off, leading to potential failures or malfunctions in machinery. However, the serrated edges of a serrated flange nut dig into the surface of the material and create friction that counters the forces trying to loosen the nut.

Furthermore, the installation of these lock nuts is straightforward. They can be easily tightened using standard tools, and due to their design, they do not require a location for additional washers or securing measures. This simplicity translates into efficiency during assembly and maintenance processes.

serrated flange lock nut

Applications

Serrated flange lock nuts are versatile and find extensive use across various industries. They are especially popular in automotive, aerospace, construction, and machinery sectors. In automotive applications, these nuts are often utilized to secure critical components such as engines, suspensions, and transmissions, where even the slightest loosening can lead to catastrophic failures.

In the aerospace industry, where safety and reliability are paramount, serrated flange lock nuts offer a robust solution for fastening components in high-vibration environments. Similarly, in construction, these lock nuts are essential for keeping structural elements securely fastened, ensuring the stability and safety of buildings and infrastructure.

Additionally, in machinery and manufacturing environments, these lock nuts are used in assembling industrial equipment where vibrations and movement are prevalent. Their ability to maintain tightness under these conditions makes them an indispensable companion for engineers and maintenance personnel.

Conclusion

The serrated flange lock nut is an exemplary fastener designed for performance under demanding conditions. Its unique combination of a serrated flange and resilient material allows it to deliver superior locking capability while simplifying the assembly process. Whether in automotive, aerospace, construction, or industrial applications, these lock nuts offer a reliable solution that enhances the longevity and safety of various assemblies.

Investing in high-quality serrated flange lock nuts is crucial for manufacturers and engineers seeking to ensure the integrity of their products. With a proven design and versatility across industries, the serrated flange lock nut stands out as a top choice for secure fastening.

Latest news

-

Premium Fasteners Manufacturer | AI-Driven Solutions

NewsAug.01,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | High Strength, Corrosion Resistance

NewsAug.01,2025

-

High-Strength Hot Dip Galvanized Bolts - LongZe | Corrosion Resistance, Custom Sizes

NewsAug.01,2025

-

Best Self Tapping Screws for Drywall - Fast & Secure Installation

NewsJul.31,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&Customization

NewsJul.31,2025

-

Hot Dip Galvanized Bolts-Hebei Longze Metal Products|Corrosion Resistance&High Strength

NewsJul.31,2025