rotating flange nut

Nov . 14, 2024 00:00 Back to list

rotating flange nut

The Innovative Design of Rotating Flange Nuts An In-Depth Exploration

In the rapidly evolving world of mechanical engineering, innovative components play a vital role in enhancing performance, safety, and efficiency. Among these components, the rotating flange nut has emerged as a significant invention that addresses various challenges in bolted connections. This article will explore the design, functionality, applications, and advantages of rotating flange nuts, shedding light on why they have become indispensable in modern engineering.

Understanding the Rotating Flange Nut

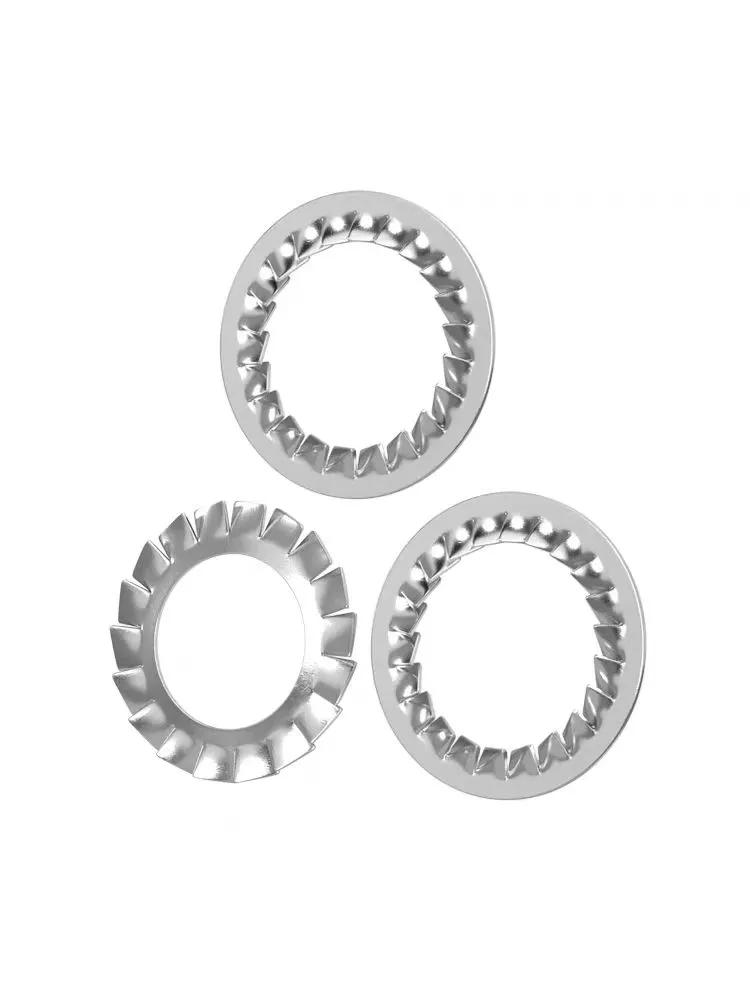

At its core, a rotating flange nut is a specialized fastener designed to provide enhanced locking capabilities in structures where high rotational forces are present. Unlike traditional nuts, which remain static once secured, the rotating flange nut integrates a unique mechanism that allows the flange—which is often wider and incorporates grooves or teeth—to rotate independently from the locking mechanism. This provides a significant advantage in applications subjected to vibrations and dynamic loads.

The design of rotating flange nuts can vary significantly, but they typically consist of a central threaded portion that fits onto a bolt and an attached flange that serves to distribute pressure. This distributed force helps reduce stress on individual components, thereby preventing failure due to over-torquing or wear.

Applications Across Industries

Rotating flange nuts find their place in various industries, including automotive, aerospace, construction, and marine engineering. In the automotive sector, they are used to secure wheel assemblies, ensuring that even under the stress of rapid acceleration, deceleration, and uneven terrain, the nuts remain securely fastened. In aerospace, rotating flange nuts are pivotal in securing critical components where reliability is paramount, as any failure could have disastrous consequences.

The construction industry also benefits from the use of rotating flange nuts, particularly in high-rise buildings and bridges where structural integrity is vital. These fasteners provide the necessary robustness to withstand environmental stresses, such as wind and seismic activity. Furthermore, in the marine industry, this technology ensures that components on vessels remain intact despite harsh conditions at sea.

Advantages of Rotating Flange Nuts

The use of rotating flange nuts offers several notable advantages

rotating flange nut

1. Enhanced Stability The design of rotating flange nuts promotes stability and reduces the likelihood of loosening due to vibrations or cyclical loads. This is particularly crucial in applications where safety cannot be compromised.

2. Load Distribution The larger surface area of the flange helps distribute the load over a wider area, decreasing the risk of localized stresses that can lead to deformation or failure of the materials being joined.

3. Ease of Installation Many rotating flange nuts are designed for easy installation and removal, which simplifies maintenance and reduces labor costs. This ease of use also contributes to faster assembly times in large-scale projects.

4. Resistance to Corrosion Many rotating flange nuts are manufactured from materials that offer excellent resistance to corrosion, increasing the longevity and reliability of the connection in adverse environments.

5. Cost-Effectiveness Although the initial investment in rotating flange nuts may be higher compared to traditional nuts, their durability and reduced maintenance needs lead to long-term cost savings.

The Future of Rotating Flange Nuts

As technology advances, the design and application of rotating flange nuts continue to evolve. Researchers are exploring the integration of smart technologies, such as sensors that can monitor the integrity of the connection in real-time. This innovation could lead to even greater efficiencies and safety measures in critical applications.

Furthermore, advancements in materials science may enable the production of rotating flange nuts that are lighter yet stronger, improving the overall performance of engineered systems. The ongoing development will likely see these fasteners adapting to diverse and demanding environments, further cementing their place in modern engineering solutions.

Conclusion

The rotating flange nut is more than just a fastening device; it embodies the spirit of innovation in mechanical design. Its unique features and advantages make it an essential component in various industries, ensuring safety, stability, and efficiency. As engineering challenges continue to evolve, the rotating flange nut stands ready to meet new demands, securing our technological advancements for years to come.

Latest news

-

Premium Self Tapping Metal Screws: Strong & Easy Install

NewsAug.02,2025

-

Premium Fasteners Manufacturer | AI-Driven Solutions

NewsAug.01,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | High Strength, Corrosion Resistance

NewsAug.01,2025

-

High-Strength Hot Dip Galvanized Bolts - LongZe | Corrosion Resistance, Custom Sizes

NewsAug.01,2025

-

Best Self Tapping Screws for Drywall - Fast & Secure Installation

NewsJul.31,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&Customization

NewsJul.31,2025