Choosing the Right Plain Washer According to DIN 125 Standards for Your Projects

Des . 04, 2024 16:03 Back to list

Choosing the Right Plain Washer According to DIN 125 Standards for Your Projects

Understanding Plain Washers as per DIN 125 Standards

Plain washers are essential components in mechanical designs that serve various functions, primarily for load distribution, preventing damage to surfaces, and providing a smooth surface for fasteners. When it comes to industry standards and specifications, the German Institute for Standardization (Deutsches Institut für Normung e.V.) encapsulated a widely accepted set of guidelines in DIN 125. This article delves into the significance of plain washers, the specifications under DIN 125, and their applications in real-world scenarios.

What is a Plain Washer?

A plain washer, or flat washer, is typically a disc-shaped piece of metal—although plastic and other materials are also used. With a central hole to accommodate a bolt or screw, plain washers are mostly used to increase the load-bearing surface of the fastener. By doing so, they also help to prevent the fastener from loosening due to vibration, which can be crucial in high-stress environments.

Overview of DIN 125

DIN 125 is a standard that governs the specifications for plain washers made from metallic materials, particularly in terms of their dimensions, tolerances, and material properties. This standard is critical for ensuring consistency and reliability in industrial applications. The standard defines several key dimensions, including inner diameter (ID), outer diameter (OD), and thickness.

The standard specifies various classifications for washers based on their design, which can include non-domed washers for typical applications or those designed with a specific thickness for heavy-duty uses. Furthermore, the material specification is critical. DIN 125 washers are often manufactured from carbon steel, stainless steel, or other alloys, depending on the intended use environment and the specific requirements dictated by the application.

Dimensional Specifications

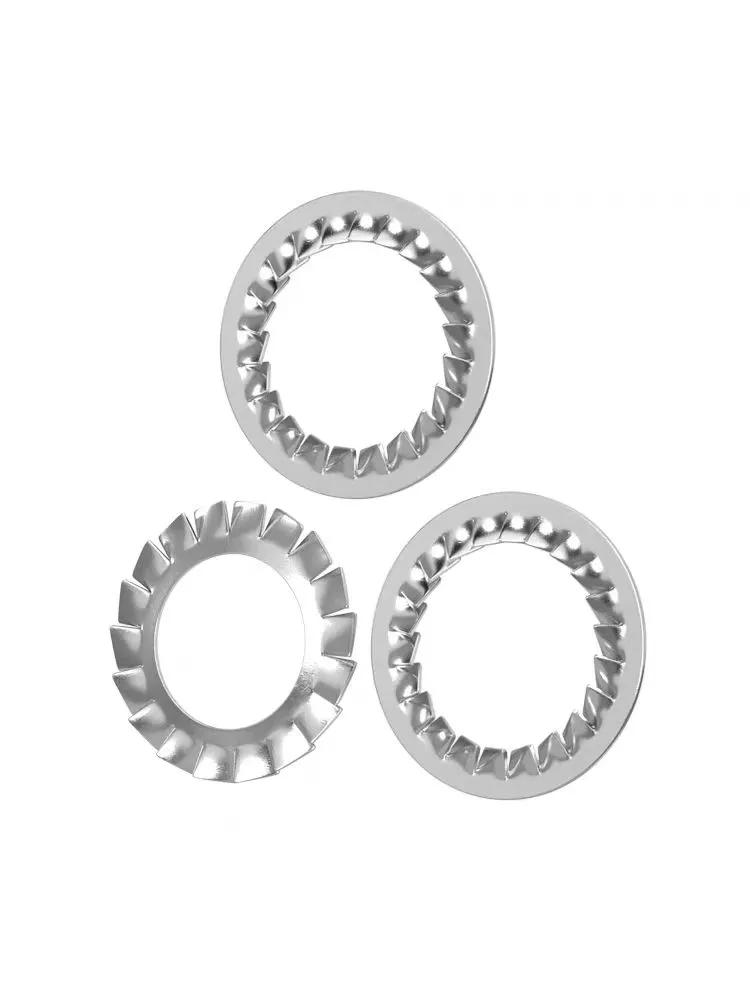

plain washer din 125

Per DIN 125, plain washers are categorized mainly based on their dimensions, which can vary significantly. Common sizes include M3, M4, M5, M6, and larger, each designated for use with corresponding bolts. The outer diameter typically ranges from 7 mm to more than 50 mm, while the thickness can range from 1 mm to 5 mm or more, depending on the specific washer's application.

It is essential to choose a washer of the correct size, as this can affect the performance of the assembly. A washer that is too small may not adequately distribute load and could lead to structural failure, while one that is too large could cause unnecessary protrusions and snagging points in assembly.

Material Considerations

When selecting washers, the material is as important as the dimensions. DIN 125 washers are often made from different grades of carbon steel with a zinc coating for corrosion resistance or stainless steel for higher strength and better corrosion resistance properties. Depending on the application and environment—such as exposure to moisture or chemicals—different material types might be necessary to ensure longevity and performance reliability.

Applications of DIN 125 Washers

The versatility of plain washers makes them suitable for various applications across multiple industries. In the automotive sector, they are used to secure components, distribute loads from fasteners, and enhance the strength of joints. In construction, they help stabilize structural elements and maintain integrity under load. Additionally, they play a vital role in electronics, machinery manufacturing, and plumbing systems.

Conclusion

Understanding the specifications defined by DIN 125 for plain washers is crucial for engineers and designers who are involved in creating efficient and reliable mechanical systems. By focusing on the material properties, precise dimensions, and appropriate use cases, one can ensure the effectiveness of these seemingly simple components. As industries evolve, so will the requirements for components like plain washers, making it imperative for professionals to stay informed about standards and improvements in washer technology. In summary, while they may appear to be minor elements within an assembly, their role in load distribution, protection of surfaces, and enhancement of assembly integrity cannot be overstated.

Latest news

-

Premium Self Tapping Metal Screws: Strong & Easy Install

NewsAug.02,2025

-

Premium Fasteners Manufacturer | AI-Driven Solutions

NewsAug.01,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | High Strength, Corrosion Resistance

NewsAug.01,2025

-

High-Strength Hot Dip Galvanized Bolts - LongZe | Corrosion Resistance, Custom Sizes

NewsAug.01,2025

-

Best Self Tapping Screws for Drywall - Fast & Secure Installation

NewsJul.31,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&Customization

NewsJul.31,2025