M10 x 1.25 Flange Nut for Secure Fastening Applications and Projects

Des . 11, 2024 04:27 Back to list

M10 x 1.25 Flange Nut for Secure Fastening Applications and Projects

Understanding M10 20 X 1.25 Flange Nut Features, Applications, and Benefits

When it comes to fastening technology, a wide range of components plays a crucial role in ensuring the stability and reliability of mechanical structures. One such essential component is the M10 20 x 1.25 flange nut. This article will explore the specifications, features, applications, and advantages of this particular type of nut, which is widely used in various industrial and DIY projects.

Specifications

The M10 20 x 1.25 flange nut signifies several key characteristics that define its dimensions and usability. The M10 indicates that the nut is designed to fit a metric bolt with a nominal diameter of 10 millimeters. The 20 specifies the number of threads per inch (TPI), and 1.25 denotes the pitch of the threads in millimeters, which is the distance from one thread crest to the next. Nuts that follow this specification are often used for securing components in a variety of settings due to their strength and versatility.

Design Features

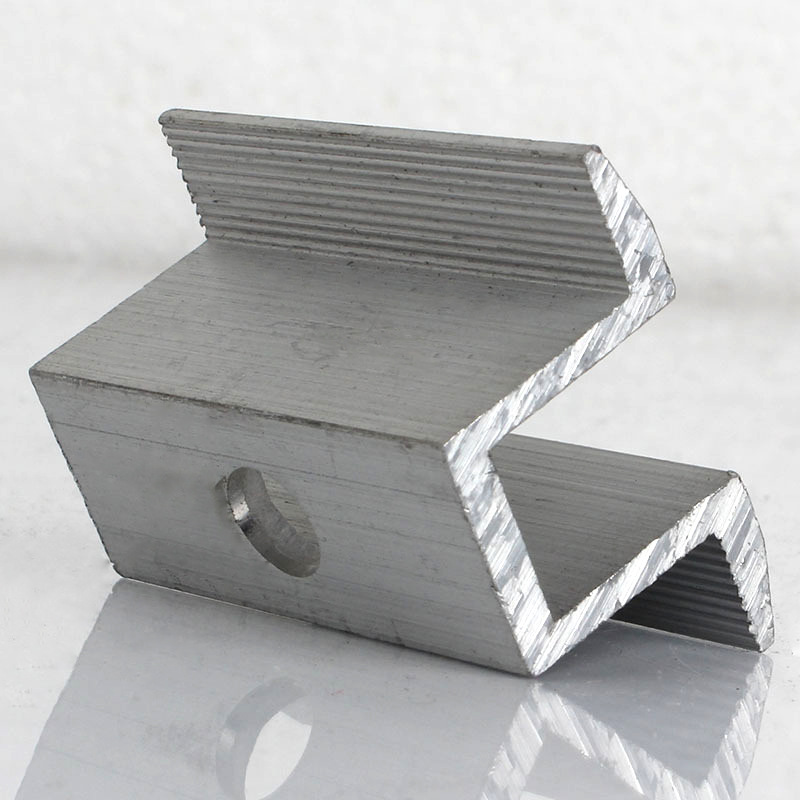

One of the most notable features of the M10 flange nut is its integral flange. The flange acts as a built-in washer, providing a larger surface area for load distribution. This feature minimizes the risk of damage to the connected materials and prevents the nut from pulling through. The flange design is particularly beneficial when dealing with softer materials that might deform under pressure. Additionally, the flange aids in reducing the possibility of loosening due to vibration, making it an excellent choice for applications in high-vibration environments.

Flange nuts are typically made from various materials, including steel, stainless steel, and sometimes even nylon or other composites. The choice of material affects the nut's strength, corrosion resistance, and overall suitability for certain environments. For instance, stainless steel variants offer added corrosion resistance, making them ideal for outdoor applications or environments where moisture is a concern.

Applications

M10 flange nuts find use in a myriad of applications across different industries. Here are a few notable examples

1. Automotive Industry In vehicles, M10 flange nuts are frequently used to secure various components such as engines, suspensions, and body frames. Their ability to withstand vibrations makes them particularly valuable in automotive applications.

m10 x 1.25 flange nut

2. Construction In construction, these nuts are used for securing beams, trusses, and other structural elements. Their reliability and strength are crucial for maintaining the integrity of buildings and structures.

3. Machinery Machinery components often require secure fastening to ensure operational efficiency. M10 flange nuts are common in the assembly of manufacturing equipment, conveyor belts, and other industrial machinery.

4. Furniture Assembly Many modern furniture designs incorporate metal components, and using M10 flange nuts allows for strong and stable construction of various furniture items.

5. DIY Projects For DIY enthusiasts, M10 flange nuts are often a staple in personal projects, from building custom furniture to manufacturing homemade machinery.

Advantages

The use of M10 flange nuts comes with numerous advantages. Their larger bearing surface helps to distribute load evenly, reducing stress on the material. This feature contributes significantly to the longevity of the components they secure. Moreover, they are easier to install compared to standard nuts since the flange guides the nut during tightening, helping to ensure a precise fit.

In addition, the design of flange nuts provides excellent resistance to loosening caused by vibration, which is critical in applications where stability is paramount. Finally, they are available in a range of materials and finishes, allowing users to select the most appropriate option for their specific environment and needs.

Conclusion

M10 20 x 1.25 flange nuts are indispensable components in various industries due to their reliable performance, ease of use, and protective design. Whether in automotive applications, construction projects, machinery assembly, or personal DIY tasks, these nuts provide the strength and stability required for effective fastening. Understanding their features and applications can help ensure the successful completion of projects with safety and durability in mind. When selecting fasteners, considering the unique benefits of M10 flange nuts can lead to improved outcomes and enhanced structural integrity.

Latest news

-

Premium Self Tapping Metal Screws: Strong & Easy Install

NewsAug.02,2025

-

Premium Fasteners Manufacturer | AI-Driven Solutions

NewsAug.01,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | High Strength, Corrosion Resistance

NewsAug.01,2025

-

High-Strength Hot Dip Galvanized Bolts - LongZe | Corrosion Resistance, Custom Sizes

NewsAug.01,2025

-

Best Self Tapping Screws for Drywall - Fast & Secure Installation

NewsJul.31,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&Customization

NewsJul.31,2025