flange nut 10mm

Jan . 20, 2025 06:23 Back to list

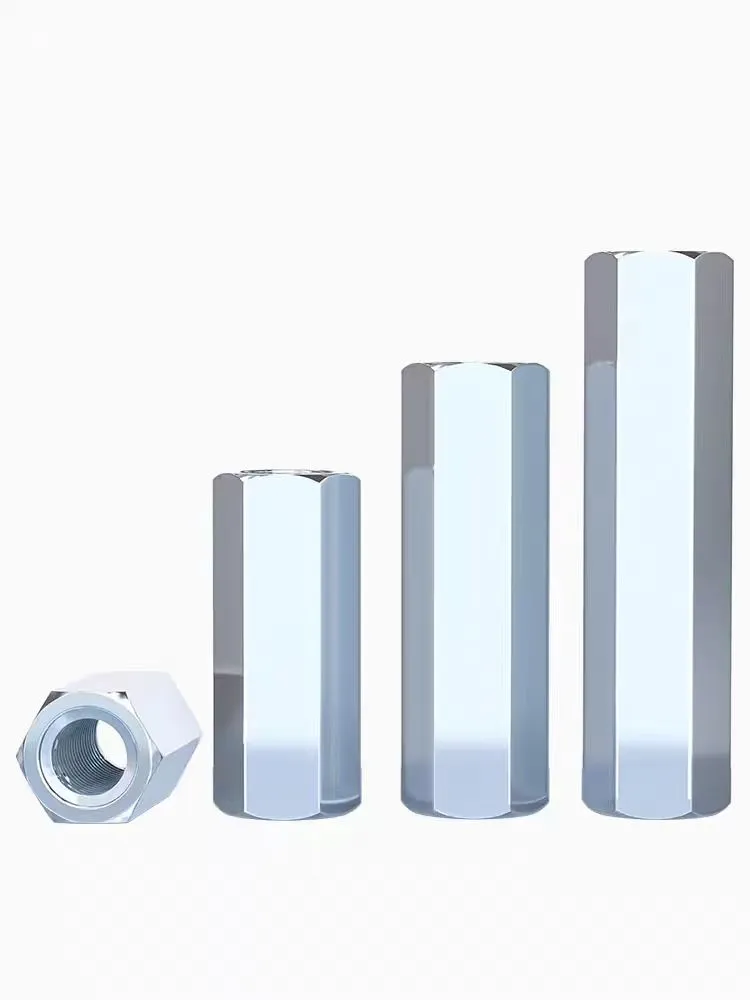

flange nut 10mm

Navigating the Intricacies of 10mm Flange Nuts A Comprehensive Guide

One of the standout advantages of using a flange nut is its ability to simplify system assembly. In practical scenarios, this can translate to reduced labor costs and time efficiency. Moreover, the inherent design reduces the need for additional washers, streamlining the hardware inventory. These factors are especially relevant in high-volume industries like automotive manufacturing or large-scale construction projects, where efficiency and reliability are paramount. In practical applications, the 10mm flange nut finds usage across diverse industries. It is prevalent in automotive assemblies, particularly in securing engine components, exhaust systems, and suspension systems. Its reliability and ease of use make it a favorite among engineers and mechanics alike, ensuring that mechanical loads are distributed evenly, thereby enhancing component lifespan. When it comes to authoritativeness, seasoned professionals in the manufacturing and engineering sectors often advocate for the use of flange nuts in projects requiring a superior fastening solution. This endorsement highlights the trust and reliability these components have accrued over years of proven service. Case studies and field data consistently showcase the superior performance of flange nuts in maintaining tight engagements even under dynamic loads and high-vibration environments. Trustworthiness in product quality is another critical facet, emphasized by the rigorous manufacturing standards adhered to by reputable manufacturers. Ensuring that the 10mm flange nuts meet or exceed ISO or DIN specifications is vital for maintaining quality assurance and safety standards across various applications. Additionally, working with trusted suppliers who provide traceability and accountability for their products further reinforces this trust. In conclusion, for those navigating the complex world of mechanical fastening, the 10mm flange nut represents a blend of practicality, robustness, and reliability. Its distinct advantages and broad range of applications make it a staple in the toolkit of professionals across multiple industries. Whether you are an engineer ensuring the integrity of an assembly or a purchasing manager seeking cost-effective solutions, the 10mm flange nut provides an answer grounded in engineering excellence and trusted performance.

One of the standout advantages of using a flange nut is its ability to simplify system assembly. In practical scenarios, this can translate to reduced labor costs and time efficiency. Moreover, the inherent design reduces the need for additional washers, streamlining the hardware inventory. These factors are especially relevant in high-volume industries like automotive manufacturing or large-scale construction projects, where efficiency and reliability are paramount. In practical applications, the 10mm flange nut finds usage across diverse industries. It is prevalent in automotive assemblies, particularly in securing engine components, exhaust systems, and suspension systems. Its reliability and ease of use make it a favorite among engineers and mechanics alike, ensuring that mechanical loads are distributed evenly, thereby enhancing component lifespan. When it comes to authoritativeness, seasoned professionals in the manufacturing and engineering sectors often advocate for the use of flange nuts in projects requiring a superior fastening solution. This endorsement highlights the trust and reliability these components have accrued over years of proven service. Case studies and field data consistently showcase the superior performance of flange nuts in maintaining tight engagements even under dynamic loads and high-vibration environments. Trustworthiness in product quality is another critical facet, emphasized by the rigorous manufacturing standards adhered to by reputable manufacturers. Ensuring that the 10mm flange nuts meet or exceed ISO or DIN specifications is vital for maintaining quality assurance and safety standards across various applications. Additionally, working with trusted suppliers who provide traceability and accountability for their products further reinforces this trust. In conclusion, for those navigating the complex world of mechanical fastening, the 10mm flange nut represents a blend of practicality, robustness, and reliability. Its distinct advantages and broad range of applications make it a staple in the toolkit of professionals across multiple industries. Whether you are an engineer ensuring the integrity of an assembly or a purchasing manager seeking cost-effective solutions, the 10mm flange nut provides an answer grounded in engineering excellence and trusted performance.

Next:

Latest news

-

Hot Dip Galvanized Bolts-About LongZe|High Strength, Corrosion Resistance

NewsJul.30,2025

-

High-Strength Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, Customization

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

High-Strength Hot-Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, High Strength

NewsJul.30,2025